PLACA DE OCULAR-SS-M16-135MM-SIN PERNOS

PLACA DE OCULAR-SS-M16-135MM-SIN PERNOS

Product Code

SKU:105.106.004

En existencias

No se pudo cargar la disponibilidad de retiro

** NO SE SUMINISTRA NINGÚN SOPORTE DE PARED CON ESTA PIEZA **

Esta placa de ojo de acero inoxidable proporcionará un punto de anclaje de placa de pared adecuado para cables catenarios de hasta 10 mm a lo largo de una calle o vía pública. La fijación correcta ayudará a cumplir con el Código de prácticas de la Sociedad de topógrafos del condado para la resistencia de la fijación de pernos de ojo.

- Placa de ojal de acero inoxidable de grado marino A4-AISI como punto de anclaje para tender cables catenarios de hasta 10 mm a través de una calle o vía pública

- Diseñado para ubicarse en el medio y abarcar tres hileras de ladrillos para lograr la máxima resistencia.

- Equipado con perno de ojo M16 de acero inoxidable

- Adecuado para fijación a pared sobre mampostería y hormigón.

- Carga máxima 700 kg

- Perfecto para la instalación segura de festones y tramos de catenaria de hasta 10 mm y otras aplicaciones de suspensión aérea, así como para amarrar embarcaciones.

- Cada placa ocular tiene su propio número de serie único.

- Altamente resistente a la corrosión.

- Atractivo y fácil de instalar.

Descargue nuestra hoja de datos de uso seguro para instalar tramos de catenaria de 10 mm en una vía pública.

Applications & Advice

Applications & Advice

Anchor Positioning:

Any Anchors used to support tensile loads should be located at least one full masonry unit from vertical (side of the wall) in the brickwork which should be the equivalent of 280mm and 2000mm from the horizontal side (top of the wall). Spacing between Anchors should be chosen to avoid 2 anchors in the same brick.

Install always into brickwork and not into Mortar. In the extreme event that you are unable to do this the following approach sanctioned by an Engineer is possible:

Choose an anchor with a diameter significantly larger than the width of the mortar joints, e.g.

>14mm in a 10mm joint.

• Fix into the base of the junction between bed and perpendicular joints

• Proof tests must be carried out, on each individual anchor

Inspection and testing:

Anchor points should be inspected at intervals of no longer than 12 months, if the anchor points have not been used in the preceding 12 months this can be deferred until prior to the next point of use.

Generally, inspection should include the following aspects:

• Test loads to be applied*, usually to be the proof test load applied at the time of installation. In the case of a square plate, it must be made clear whether or not the test load is applied to the plate as a whole or to the individual anchors.

• Eyebolts to be removed and examined for wear or other defects and to confirm that they have been installed in an internally threaded socket.

• Eyebolts to be checked for tightness (e.g. that they cannot be unscrewed by hand)

• Nuts on stud anchors to be checked for nominal tightness (e.g. residual torque of approximately 10Nm).

• Visual inspection of componentry for rust.

• Visual inspection of the surrounding substrate to check for damage including cracks in masonry or mortar joints

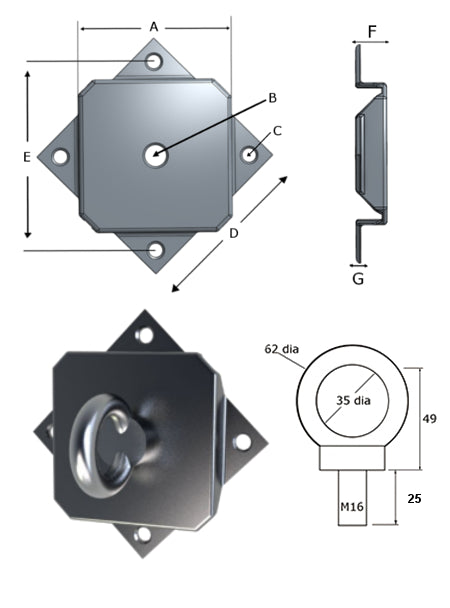

Dimensions

Dimensions

A: 119mm

B: 17mm

C: 12.5mm

D: 130mm

E: 146mm

F: 26mm

G: 4mm

Downloads

Downloads