Irongrip Wire Rope Clamp BG-S-SS Stainless Clips

Irongrip Wire Rope Clamp BG-S-SS Stainless Clips

Precio habitual

£1.65 GBP

Precio habitual

Precio de oferta

£1.65 GBP

Los gastos de envío se calculan en la pantalla de pago.

Product Code

SKU:260.055.002

Cantidad

245 en existencias

No se pudo cargar la disponibilidad de retiro

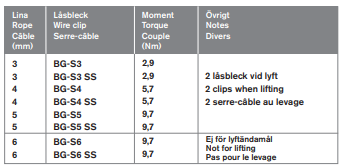

IRONGRIP BG-S-SS Lifting Quality Wire Rope Clip for Stainless Cable 2mm to 6mm Diameter Detailed Description

- 316 Stainless Steel Wire Rope Clips Perfect for Smaller Diameters with sizes suitable for 2mm to 6mm cable.

- Easy to install on-site.

- Unique Construction Provides Extra Strength.

** 6mm Not Recommended for Lifting **

Extensive load testing shows that IronGrip Wire Rope Clips withstand twice the load capacity compared to other wire rope grips on the market. IronGrip clips are perfect for stabilizing or suspending loads supported by cable and wire rope such as Construction sites, Gymnasiums and Display & Signage. The BG-S-SS unique shape creates a strong termination without damaging the wire.

The high quality coating ensures that the Wire Clips are long lasting and low maintenance.

Applications & Advice

Applications & Advice

- We recommend using a socket drive to tighten nuts

- Applications not used for lifting: one clip per termination

- Applications used for lifting: two clips per termination - applies to both static (hanging load) and dynamic lifting

- *Please note 6mm clips not suitable for lifting*

Dimensions

Dimensions

Downloads

Downloads

Technical Information

Technical Information

Fitting

- 1. The wire clip can be used with or without thimble.

- 2. Check that the rope and clip are undamaged and that the threads have been cleaned and lubricated. Thread lubrication is particularly important in lifting service to obtain the correct tractive force in the screws.

- 3. The length of the loop (h) should, when unloaded, be at least approx. 15 x the rope diameter measured from the clip to the inner curve of the loop (diagram 1). If the rope is to be fastened around a large object, ensure that the pitch angle (v) at the clip is no greater than 45º.

- 4. If more than one clip is to be fitted, the distance between them must be at least 3 x the rope diameter. If thimbles are used, the distance between the clip closest to the loop and the thimble must be at least 1.5 x the rope diameter. Let the end of the rope project from the last clip by at least 5 x the rope diameter.

- 5. Fasten the clip onto the rope as shown in diagram 2, with a part of the rope on either side of the screws, and tighten the nuts alternately. The correct torque is given in the table. The nuts should be tightened with a torque spanner if the termination is to be used for lifting.

Video

Video