Code 0.8 Double Copper Nickel Plated Ferrule - 115.000.080

Code 0.8 Double Copper Nickel Plated Ferrule - 115.000.080

Product Code

SKU:115.000.080

7910 in stock

Couldn't load pickup availability

Code 0.8 Nickel-Plated Double Copper Ferrule - Silver Finish.

Suitable for use with 0.54mm - 0.75mm cable when creating ferrule secured eye termination (Loops).

Nickel-Plated copper ferrules are best suited for use with Stainless Steel cable. They offer a more cost effective solution to Stainless Ferrules where there's a need to avoid Galvanic corrosion.

Available in sizes 0.8 - 1.

Suitable for use with our miniature cable range.

To fit, insert cable through one side of the ferrule then back through the other to form an eye. Hold the ferrule perpendicular to the die face in the hand tool and press/crimp.

Applications & Advice

Applications & Advice

Code 0.8 Nickel Plated Double Copper Ferrule - 115.000.080

Ideal for small-scale rigging, display systems, and other precision cable assemblies.

Nickel-plated copper is copper coated with a layer of nickel, offering a combination of formability with significantly improved durability, corrosion resistance, and wear resistance.

These properties make it valuable in environments where cables, fittings, and related components are exposed to harsh conditions, mechanical stress, or corrosive elements.

Recommended Tool - 115.207.023 Hand Crimper

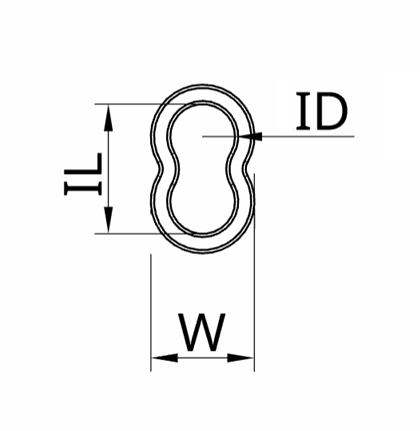

Dimensions

Dimensions

ID - 1mm

IL - 2.4mm

W - 2.35mm

Downloads

Downloads

Technical Information

Technical Information

During the pressing process, small areas of flashing may appear on the finished crimp. Do not re-press the ferrule, as re-pressing may reduce the overall strength of the termination.

Benefits of Nickel Plating on Copper

Improved durability:

Nickel is harder and more wear-resistant than copper, providing a protective surface that reduces abrasion and mechanical erosion.

Enhanced corrosion resistance:

The nickel coating shields the copper from oxidation and corrosion, especially in marine, industrial, and outdoor environments.

Increased wear resistance:

The nickel layer helps prevent surface degradation over time, which is essential for components used in high-vibration or high-movement cable systems.

Better joinability:

Nickel-plated copper maintains good compatibility with brazing, soldering, and other joining processes commonly used in fabricating cable accessories and assemblies.

Improved strength:

Nickel plating increases surface strength and structural integrity, helping components withstand demanding loads and long-term use.

Video

Video

Dimensions