TECNI® Catenary Eye Plate - M16 X 135MM Folded Eyeplate with M12 Anchor Bolts - 105.106.002

TECNI® Catenary Eye Plate - M16 X 135MM Folded Eyeplate with M12 Anchor Bolts - 105.106.002

Product Code

SKU:105.106.002

Low stock: 7 left

Couldn't load pickup availability

This Stainless Steel Eye Plate will provide a suitable wall plate anchorage point for spanning up to 10mm catenary cables across a street or Public Highway. Correct fixing will aid compliance with the County Surveyors' Society Code of Practice for Eyebolt fixing strength.

- A4-AISI 316 marine grade stainless steel eye plate as anchorage point for spanning up to 10mm catenary cables across a street or Public Highway

- Designed to sit in the middle of, and span three courses of bricks for maximum strength

- Fitted with stainless M16 eyebolt

- Secured to the wall with 12mm anchor bolts with Nyloc lock nuts

- Suitable for wall fixing to masonry and concrete

- Max Load 700kgs

- Perfect for safe installation of festoon & up to 10mm catenary spans and other overhead suspension applications as well as mooring boats

- Each eye plate has its own unique serial number

- Highly corrosion resistant

- Attractive and easy to install

Applications & Advice

Applications & Advice

Anchor Positioning:

Any Anchors used to support tensile loads should be located at least one full masonry unit from vertical (side of the wall) in the brickwork which should be the equivalent of 280mm and 2000mm from the horizontal side (top of the wall). Spacing between Anchors should be chosen to avoid 2 anchors in the same brick.

Install always into brickwork and not into Mortar. In the extreme event that you are unable to do this the following approach sanctioned by an Engineer is possible:

Choose an anchor with a diameter significantly larger than the width of the mortar joints, e.g.

>14mm in a 10mm joint.

• Fix into the base of the junction between bed and perpendicular joints

• Proof tests must be carried out, on each individual anchor

Inspection and testing:

Anchor points should be inspected at intervals of no longer than 12 months, if the anchor points have not been used in the preceding 12 months this can be deferred until prior to the next point of use.

Generally, inspection should include the following aspects:

• Test loads to be applied*, usually to be the proof test load applied at the time of installation. In the case of a square plate, it must be made clear whether or not the test load is applied to the plate as a whole or to the individual anchors.

• Eyebolts to be removed and examined for wear or other defects and to confirm that they have been installed in an internally threaded socket.

• Eyebolts to be checked for tightness (e.g. that they cannot be unscrewed by hand)

• Nuts on stud anchors to be checked for nominal tightness (e.g. residual torque of approximately 10Nm).

• Visual inspection of componentry for rust.

• Visual inspection of the surrounding substrate to check for damage including cracks in masonry or mortar joints

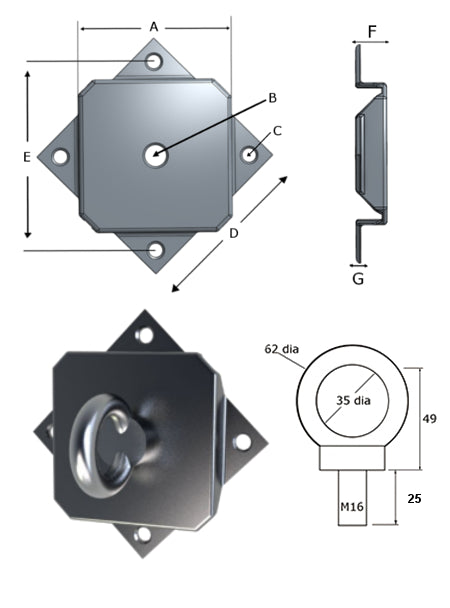

Dimensions

Dimensions

A: 119mm

B: 17mm

C: 12.5mm

D: 130mm

E: 146mm

F: 26mm

G: 4mm

Downloads

Downloads